Core Competency

Synthetic Quartz Crystal

Synthetic Quartz Crystal

Synthetic Quartz Crystal, the foundation of crystal units.

Siward is one of the few companies in the industry and the only one in Taiwan that has the complete resources to support product service from row material to finished product, from synthetic quartz growing, wafer design, processing, to packaging.

MEIDENSHA crystal factory, the former company of SIWARD JAPAN, photoed in 1980's.

Combine the advantages of Japan, Russia and China crystal growing technologies. We serve synthetic quartz crystal, chip design and finished product.

Siward has over 30 years experience of synthetic quartz crystal. Our products are widely used in electronic and optical devices, both of the leading companies in the two fields are our customers. In order to meet the market needs, we are working on the quartz bar for big size crystal quartz wafer.

Siward is the only company in Taiwan which masters the key material of crystal units - synthetic quartz crystals. We offer high quality, low impurities, and low etching density quartz bars with vast experience and expertise.

Purity Comes from Refinement.

The birth of high-quality quartz crystals, under pressure 100Mpa, 400 degrees high temperature, up to 200 days growing, recrystallization, and then high-quality crystal is born.

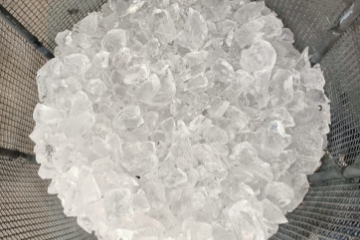

The Choice of Natural Quartz

The origin of synthetic quartz crystals is natural quartz. Choosing high-purity, high-uniformity natural quartz is the assurance for high-quality quartz crystals.

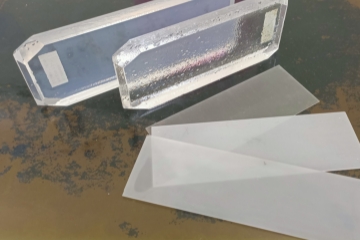

High Quality Seed Crystal Bar

Growing big size, high quality, low etching density seed crystal bar is a key factor in synthetic quartz crystals.

Accurate Parameter Design and Management

Rich experience, designing production conditions according to demand, and strict management are the guarantees of quality and safety.

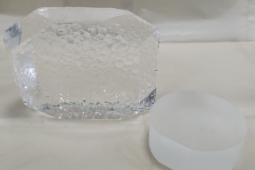

The Largest Quartz Bar in Industry

With the evolution of photolithography for miniaturized and ultra-high frequency quartz blanks, the industry has advanced from 2-inch and 3-inch to 4-inch wafers, and Siward is taking the next leap to 6-inch. Siward has mastered the growth of 6-inch AT synthetic quartz crystals, which is the largest quartz bar in industry. As one of the few companies with this capability, Siward leads the way in developing large-scale photolithography wafers for next-generation applications.

Swept Quartz Crystal

The modern space industry is rapidly evolving, Siward's Swept quartz crystals address this with exceptional radiation resistance, ensuring stable frequencies and reliable performance in demanding LEO (Low Earth Orbit) and other aerospace applications.

As the industry advances, Siward remains at the forefront, delivering innovative solutions that empower the future of space exploration and communication.

Quartz Bar SPEC

-

Quartz Bar for AT Cut

- Size 1inch~4inch

- ICD 1b~2

- ECD 1a~2

- Q 2.4M~3.0M

-

Quartz Bar for Optics

- Size 1inch~4inch

- ICD 1a~2

- ECD 1a~2

- Q 1.8M

-

Quartz Bar for TF Wafer

- Size 3inch~4inch

- ICD 1a~2

- ECD 1a~2

- Q 1.8M

-

Quartz Bar for SAW Wafer

- Size 3inch~4inch

- ICD 1~2

- ECD 1~2

- Q 1.8M